The Schaublin 13 is probably one of the most desirable small tool-room milling machines. More than 4400 machines were built between 1947 and 1988 and during this time a number of significant changes took place. All machines featured variable spindle speeds from the familiar Reeves-type belt-driven variator via a two speed gearbox and power feeds with rapids to the longitudinal (x) and vertical (z) axes.

The Schaublin 13 is probably one of the most desirable small tool-room milling machines. More than 4400 machines were built between 1947 and 1988 and during this time a number of significant changes took place. All machines featured variable spindle speeds from the familiar Reeves-type belt-driven variator via a two speed gearbox and power feeds with rapids to the longitudinal (x) and vertical (z) axes.

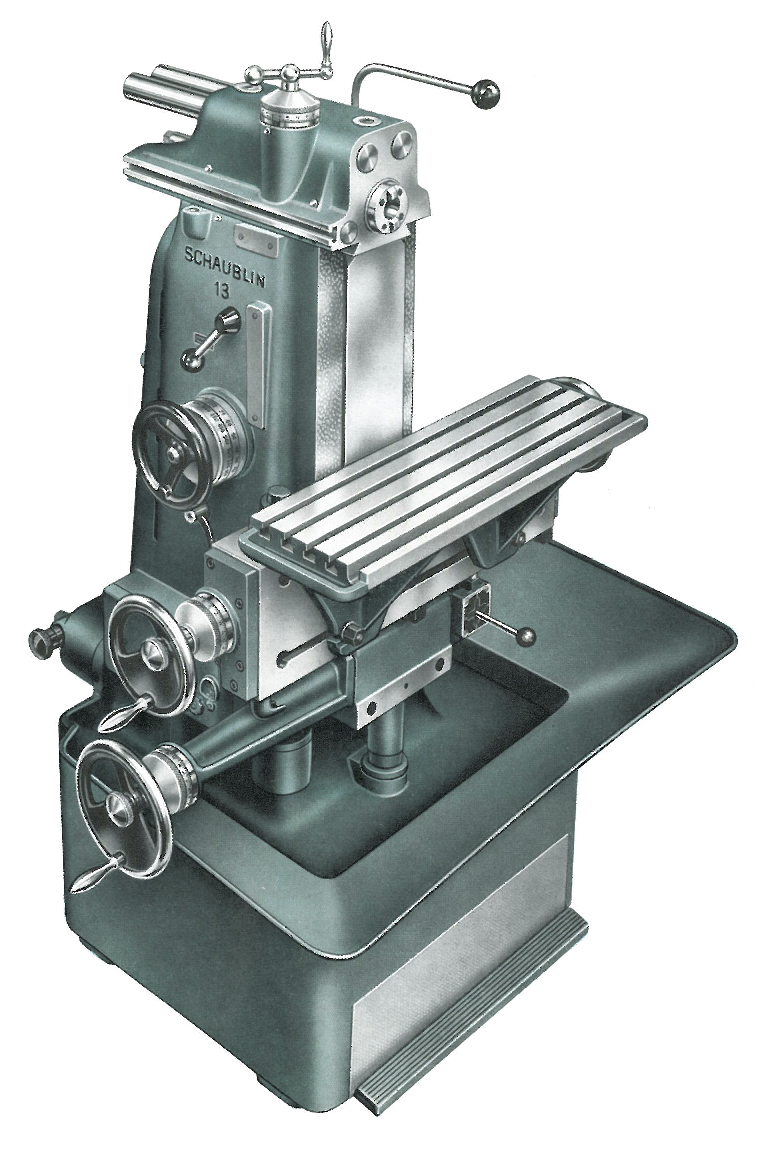

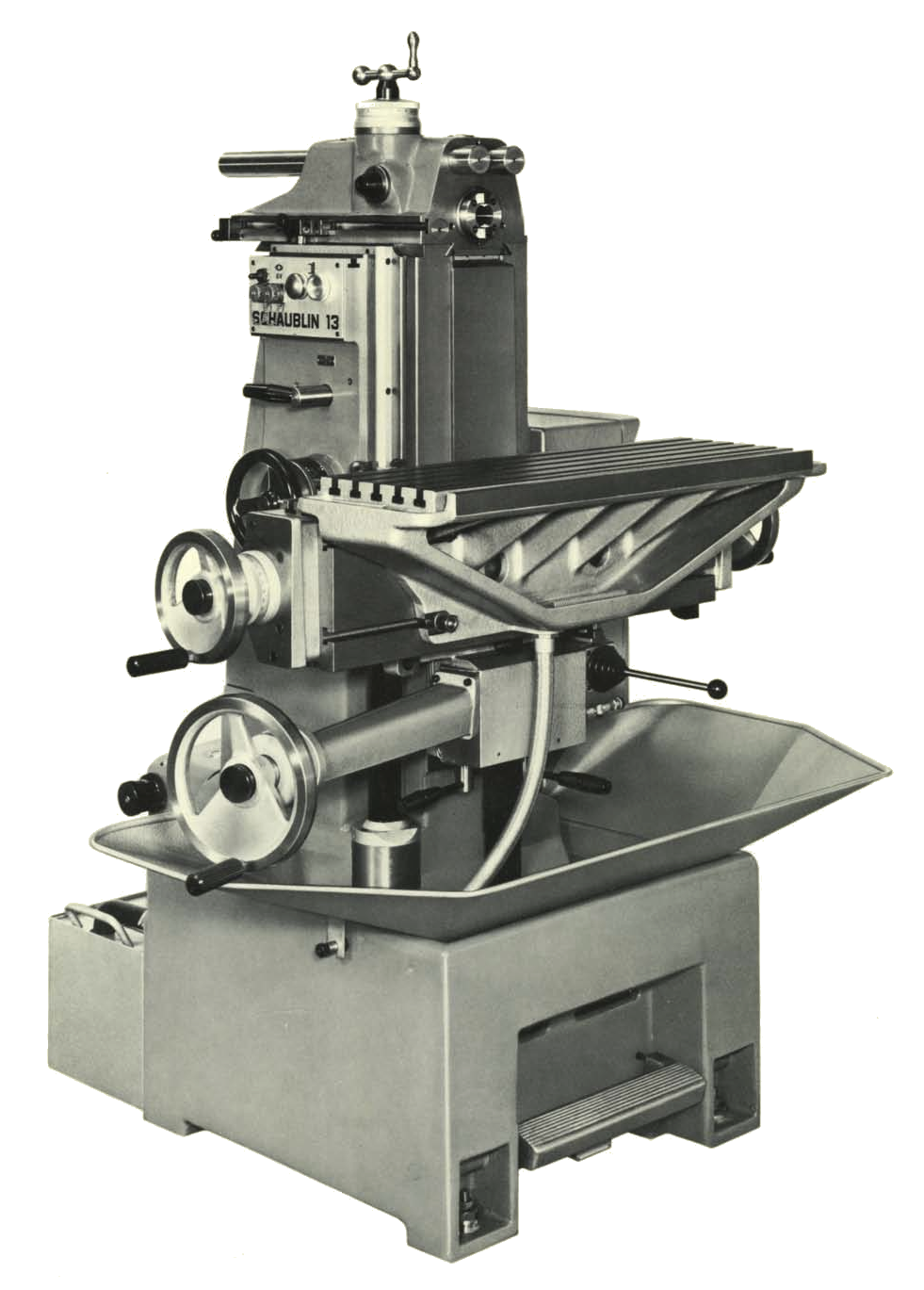

Following the “continental pattern” of universal milling machines, the 13 was built around a large  column body which carried the horizontal (y axis) and vertical (z axis) slides. The column also housed the two speed reduction gearbox and the spindle speed variator giving spindle speeds between 58 and 2000rpm. The cast-iron base, upon which the main column sat, housed the main single-speed motor which drove both the spindle and the feeds gearbox. The feeds gearbox, somewhat inconveniently located at the rear of the machine, had 8 quickly selectable feeds and featured an overload clutch as well as a clever device for preventing reversal of the feed when the motor direction was reversed. A “joy stick” mounted below the table on the left engaged feeds for both x and z axes in either direction. A separate motor, controlled by the foot-bar at the front of the machine, imparted rapid feeds. The motor can be troublesome and is difficult to work on since it is only accessible from the underside of the machine.

column body which carried the horizontal (y axis) and vertical (z axis) slides. The column also housed the two speed reduction gearbox and the spindle speed variator giving spindle speeds between 58 and 2000rpm. The cast-iron base, upon which the main column sat, housed the main single-speed motor which drove both the spindle and the feeds gearbox. The feeds gearbox, somewhat inconveniently located at the rear of the machine, had 8 quickly selectable feeds and featured an overload clutch as well as a clever device for preventing reversal of the feed when the motor direction was reversed. A “joy stick” mounted below the table on the left engaged feeds for both x and z axes in either direction. A separate motor, controlled by the foot-bar at the front of the machine, imparted rapid feeds. The motor can be troublesome and is difficult to work on since it is only accessible from the underside of the machine.

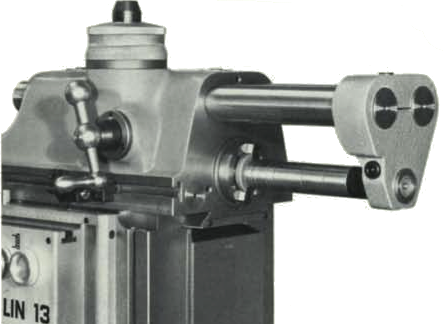

The horizontal headstock, with its unusual vertically positioned feed handle (a second horizontal station provided on later machines), had a manual travel of 150mm and carried a hardened and ground spindle featuring either a 4 Morse taper socket (early machines) or 30 ISO taper. The earlier machines had double row roller bearings and taper-roller thrust, while later machines employed angular contact bearings. The horizontal spindle also accommodated two super-finished cylinders which, with a separate casting, formed the overarm. These cylinders also loacated the swiveling vertical head (4MT on early machine 30 ISO on later machines), high-speed head and slotting head.

The horizontal headstock, with its unusual vertically positioned feed handle (a second horizontal station provided on later machines), had a manual travel of 150mm and carried a hardened and ground spindle featuring either a 4 Morse taper socket (early machines) or 30 ISO taper. The earlier machines had double row roller bearings and taper-roller thrust, while later machines employed angular contact bearings. The horizontal spindle also accommodated two super-finished cylinders which, with a separate casting, formed the overarm. These cylinders also loacated the swiveling vertical head (4MT on early machine 30 ISO on later machines), high-speed head and slotting head.

Earlier machines had travels of 260mm longitudinal (x); 310mm vertical (z); and 150mm horizontal (y). Later machines, identifiable by the vertical axis hand-wheel arm being angled away from the machine, had travels of 320mm (x), 375mm (z) and 150mm (y). The plain table had a working area of 600 x 210mm. Early machines in horizontal form and without a table weighed 440kg – later machines 740kg. Later machines also featured an extremely convenient one-shot centralised lubrication system.

Earlier machines had travels of 260mm longitudinal (x); 310mm vertical (z); and 150mm horizontal (y). Later machines, identifiable by the vertical axis hand-wheel arm being angled away from the machine, had travels of 320mm (x), 375mm (z) and 150mm (y). The plain table had a working area of 600 x 210mm. Early machines in horizontal form and without a table weighed 440kg – later machines 740kg. Later machines also featured an extremely convenient one-shot centralised lubrication system.

A good range of accessories including high-speed head, universal tilting table, dividing head, rotary table etc were available allowing just about any tool-room job to be undertaken.

A good range of accessories including high-speed head, universal tilting table, dividing head, rotary table etc were available allowing just about any tool-room job to be undertaken.

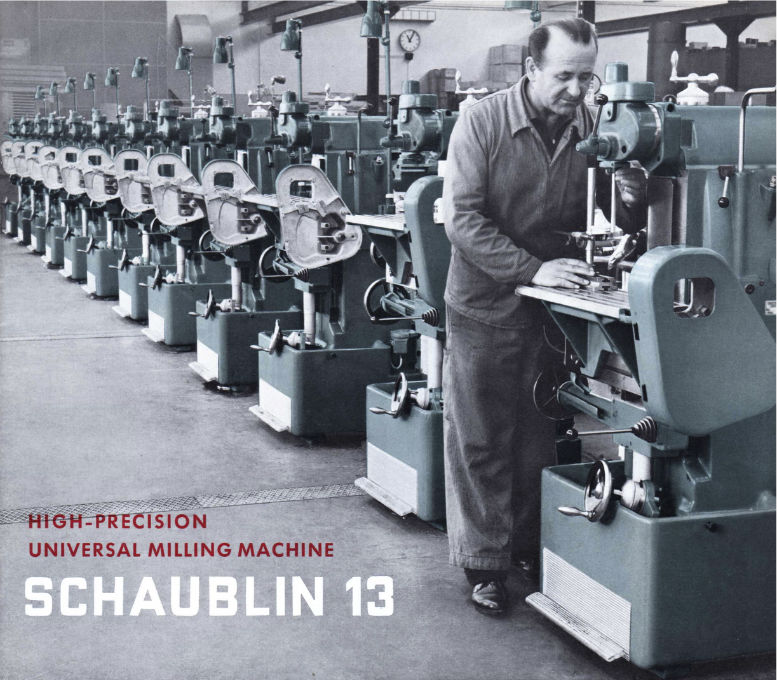

This rather nice factory photograph shows a row of machines fitted with high-speed heads. They’re also fitted with the gearbox used in conjunction with the universal dividing head for spiral milling.

This rather nice factory photograph shows a row of machines fitted with high-speed heads. They’re also fitted with the gearbox used in conjunction with the universal dividing head for spiral milling.

Really good review of the later-type Schaublin 13 mill.