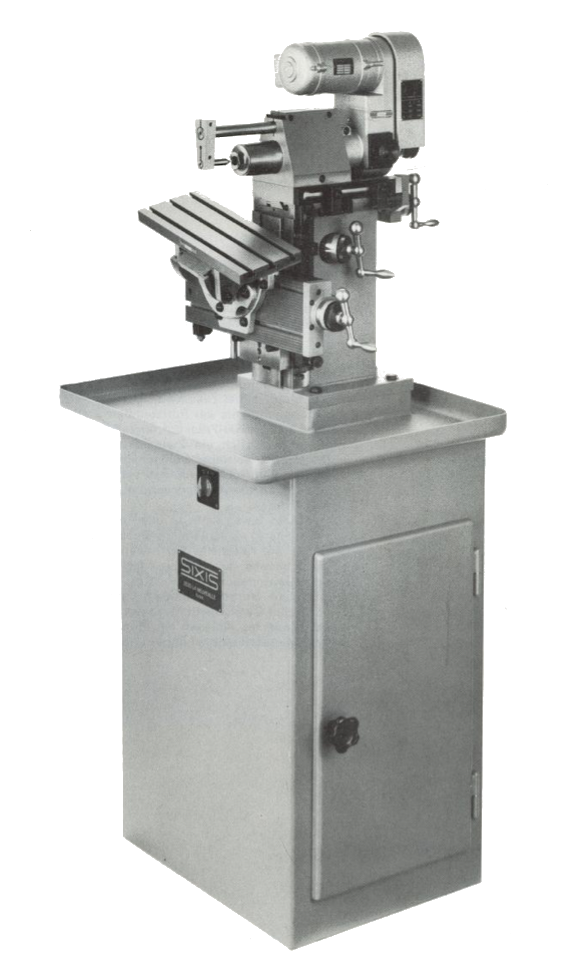

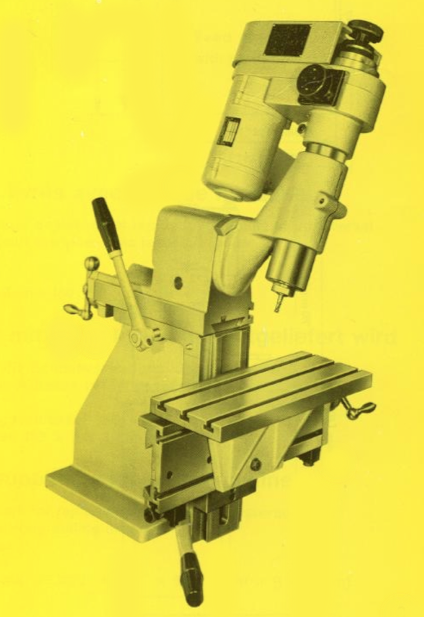

These small milling machines were very similar to the Aciera F1 but are slightly larger and of a more robust construction. Table travels at 150mm longitudinal (x), 100mm headstock slide (y) and 150mm vertical are considerable larger than those of the F1 (x=100mm, y=75mm, z=150mm). The 101’s table was secured to two T-slots running along the front of the longitudinal slide, and could be positioned anywhere along this face further increasing the machine’s capacity. Feeds were manual only by screw or lever, but unlike the Aciera F1 the Sixis did not have a balancing mechanism for the vertical slide. Stops were provided for all axes.

These small milling machines were very similar to the Aciera F1 but are slightly larger and of a more robust construction. Table travels at 150mm longitudinal (x), 100mm headstock slide (y) and 150mm vertical are considerable larger than those of the F1 (x=100mm, y=75mm, z=150mm). The 101’s table was secured to two T-slots running along the front of the longitudinal slide, and could be positioned anywhere along this face further increasing the machine’s capacity. Feeds were manual only by screw or lever, but unlike the Aciera F1 the Sixis did not have a balancing mechanism for the vertical slide. Stops were provided for all axes.

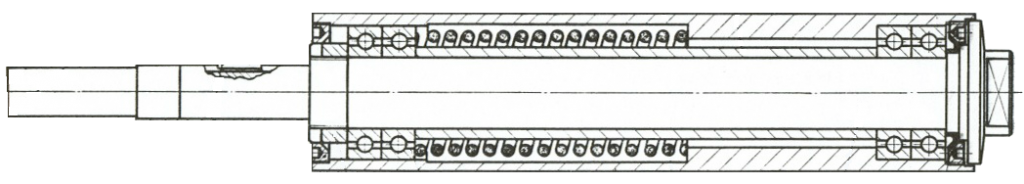

The basic design of the spindle assembly was much like the Aciera F1 and F2 quills. Like the F1 the Sixis 101 used the Schaublin W12 collet. However, by comparison at 55mm in diameter the 101 ‘s quill was much larger than the 40mm diameter F1 quill. The reason for this difference lies in the type of bearings used by each company. Aciera used a needle-roller bearing for all but the very late spindles, while Sixis employed pairs of angular contact bearings, preloaded by a spring, at each end of the spindle. This not only makes the Sixis spindle extremely rigid, but also much easier to service and recondition. The spindle gearbox gave a range of six direct and geared speeds from 125 – 4000 rpm. High speed spindle/motor assemblies without gearboxes were available giving speeds up to 15000 rpm. These machines were designed for use in the jewelry industry and a range of accessories for diamond milling were available.

‘s quill was much larger than the 40mm diameter F1 quill. The reason for this difference lies in the type of bearings used by each company. Aciera used a needle-roller bearing for all but the very late spindles, while Sixis employed pairs of angular contact bearings, preloaded by a spring, at each end of the spindle. This not only makes the Sixis spindle extremely rigid, but also much easier to service and recondition. The spindle gearbox gave a range of six direct and geared speeds from 125 – 4000 rpm. High speed spindle/motor assemblies without gearboxes were available giving speeds up to 15000 rpm. These machines were designed for use in the jewelry industry and a range of accessories for diamond milling were available.

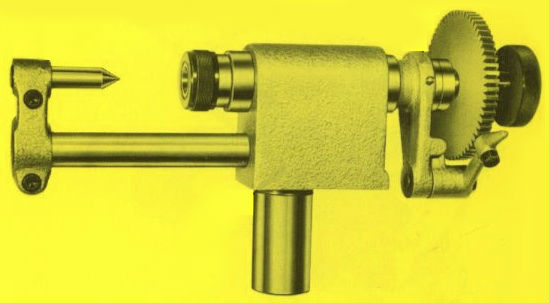

The accessories available were almost identical to those for the Aciera machine, and indeed accessories such as the indexing head are interchangeable between the two makes. These are excellent machines for horologists particularly those using the Schaublin 70 lathe.

The accessories available were almost identical to those for the Aciera machine, and indeed accessories such as the indexing head are interchangeable between the two makes. These are excellent machines for horologists particularly those using the Schaublin 70 lathe.